HGM(Hallys Glass Processing Machine) is grinding machine for glass edges of cover glass and glass substrate for touch panel which for use of Smartphone, Tablet PC, Note PC.

- 6 independent process stages

- Full automatic processing of roughing, drilling, inner and outer chamfering, finishing.

- Detected glass set position with CCD camera and corrected process profile date automatically. (patented)

- Auto Tool Changer (ATC) is installed. (MAX 10 pcs grinding stones are mountable)

- Automatic work transportation with specified loader. (patented)

- Generating process profile data easily with unique CAM (PPG).

- Intuitive operation by GUI (Graphical User Interface)

- Glass ejection system is installed for spot inspection High quality grinding process with Hallys original water nozzle. (patented)

- Reduction grinding process time with high speed spindle.

Features for HGM

▸Full automatic processing

Just 1 HGM makes possible to process even complicated shapes.

Full automatic processing of roughing, drilling, inner and outer chamfering, finishing.

Full automatic processing of roughing, drilling, inner and outer chamfering, finishing.

▸High precision process

Detected glass set position with CCD camera and corrected process profile date automatically. (patent pending)

▸User-friendliness

Intuitive operation by GUI (Graphical User Interface)

▸CAM system (PPG)

Include CAM system as standard equipment ! (additional function is also full complement)

Reduce working time at site.

Programming is not necessary, just setting up process condition.

Reduce working time at site.

Programming is not necessary, just setting up process condition.

▸Continuous process

Transport system (supply/collection) makes possible to the grinding operation continuously.

Reduction of stop time leads to a heightening of productivity.

Reduction of stop time leads to a heightening of productivity.

▸High speed and high quality processing

Water nozzle and high speed spindle of Hallys unique technology leads to high quality grinding process.

Even high speed processing is possible to keep quality stability.

Even high speed processing is possible to keep quality stability.

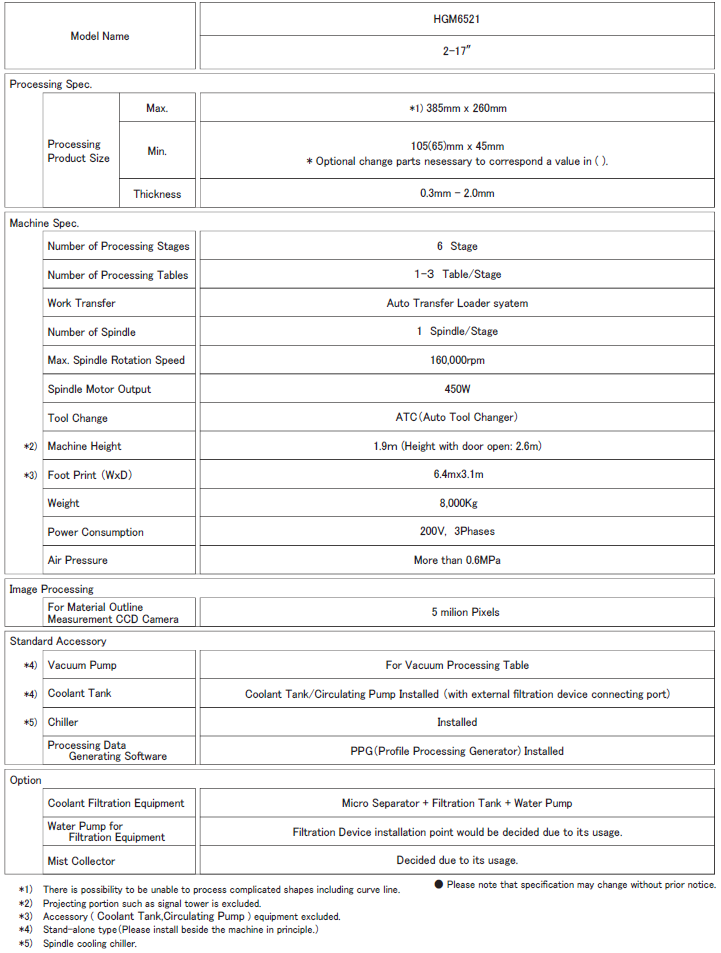

HGM6521